My Portion of the Boden-Haus is Complete!

Thursday, September 17, 2009 at 3:46PM

Thursday, September 17, 2009 at 3:46PM

It is hard to believe that the body of the Boden-Haus is complete, and my work on it is done. The last of many thousands of tamps occurred on September 8, and the wall cap and roof frame went up 5 days later. We celebrated with a champagne toast and consumed handsome and bountiful vittles. The next day, a bit over 6 months after arriving in Tennessee, I left feeling very happy about the first of my rammed earth accomplishments and very grateful to my hosts for making it possible. She's a beauty and more than I expected!

Before describing the process generally, what was learned and listing those who offered invaluable help throughout, I will describe work that was done since my last update.

The day the lower-half was completed.

A helpful but ambitious deadline of September 13th was set for the Boden-Haus. Just three weeks to the end, the wall were not even half-complete, and the process of placing the formworks and ramming on top of the lower-half of the walls was a challenge. The formworks used for the foundation cap were insufficient for the upper-half of the walls because the 3-inch lower lip the gripped the foundation cap needed to be twice as long to avoid damaging the top of the previously-rammed portion of walls. So, I made new formworks, the third set, to be used for the upper-half of the walls, and Robert and I removed corner that was damaged during this lesson. This corner was the second corner I made and was lacking sufficient clay for cohesion, so its removal was more sweet than bitter.

Once the new formworks were made and the corner was replaced, the task of ramming the upper-half of the walls was straight-forward but effortful. A bit over two weeks later, after working tirefully, the walls were complete. How sweet it felt! I spent the couple days leveling the top of the walls, and Robert and I picked up the wood for the cap and roof from a lumber mill. The cap is 3" x 15", an unusual dimension and something you can obtain only through a lumber mill.

The day the upper-half was completed, the ramming was done.

Robert, Rachel, Jacob and I worked for two days on cutting and installing the flashing (a barrier between the rammed earth and wood to prevent the untreated wood from rotting) and the wood caps. This was a bit of a challenge because I had installed vertical rebar in the upper-half of the walls to tie the cap and roof to the rammed earth. The twenty pieces of rebar were at odd intervals, but without too much trial and error of the 10', 100+ pound pieces of cap, the flashing and cap fit nicely on top of the walls. Also, per Karl Ellington's instructions, we made a mud mortar to spread on the top of the walls before installing the flashing to fill any small voids on the wall's top. This is an important step, as it allows for an even distribution of the weight of the cap and roof on the walls.

The roof was mostly the work of Herr Robert. While it still follows the general, original design of the Boden-Haus, minus the sod, he did the work of researching the types of beams, their spacings and other such design elements. Robert works hard, and it was great to hit the ground running and complete the shed roof in just two days. Of course, Mark (a neighbor of Robert and Rachel) and Noah and Justine (friends) offered great help. Noah was a professional framer, and he and Justine are the finest contractors in East Tennessee. Noah came in, with his rad tools and immense know-how, and he and Robert installed the rafter faster than you can imagine. Seriously, it was quite a site to be seen. My role was that of a gopher, and I handed them the rafters.

Those are the steps that brought the Boden-Haus to its current state. Rachel will be making a stained-glass window for the smaller window, and they will also add the other window, a door, finish the roof details and finish the floor. I can't wait to see it when it's completed.

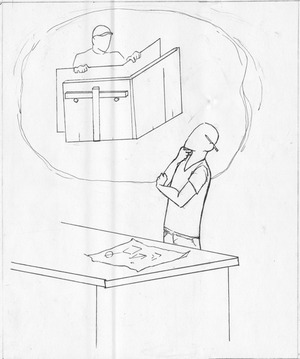

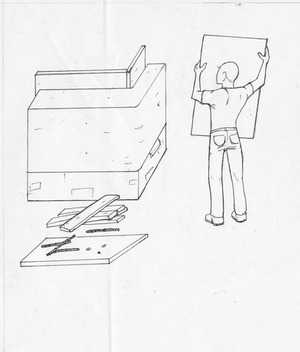

Kate, Rachel's sister, was commissioned to complete the below drawings, visual guides to the rammed earth process.

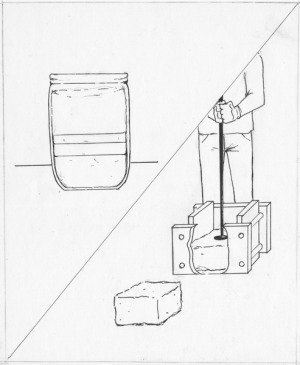

Plate 1 - Field and Lab Tests and Test Blocks

One must determine the amount of various aggregates (gravel, sand, silt and clay) in the soil to be used. There are a number of field and laboratory tests that can be used for this purpose. Once I thought I had the right mix, I made test blocks to see whether there was cracking and whether there was sufficient cohesion. Despite the tests, it turns out that the first two corners I made were lacking in clay, and they had to be torn down. More careful laboratory tests and more careful test blocks might have prevented this most unpleasant step backwards. In the end, the soil excavated was too silty and clayey to be rammed without adding large aggregates. Fortunately, we had access to 200 tons of sand and bought 7 tons of 1/2" gravel. Unfortunately, I added too much sand and gravel initially. In the end, the right mix for us was 2 parts of excavated soil, 1 part sand and 1 part gravel.

Plate 2 - Designing Formworks

As I already mentioned, I went through three sets of formworks. This is expensive, discouraging and unnecessary. The first formwork I made was of 2" x 12" pieces of wood stacked vertically, so the total height was 33". It was heavy, had too many pieces of wood acting independently and was very difficult to plumb and level. I was happiest with 3/4" flooring plywood as the internal frame of the formwork. It was much easier to plumb and level and much lighter.

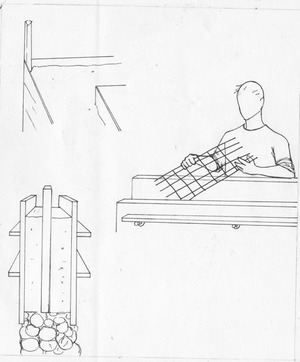

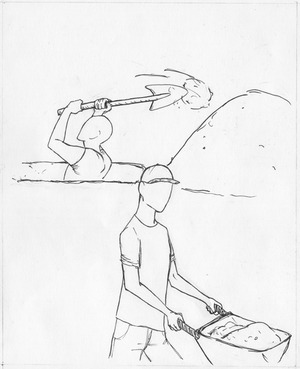

Plate 3 - Sourcing Soil

Once I knew the make-up of the soil to be used, I excavated about 6 or 7 tons of it. This was sufficient to complete the lower-half of the Boden-Haus. However, the rest of the soil came from excavated soil from another work site. It was brought in a dump truck, which saved a lot of time. Because of the higher clay content and lower silt content, the mix seemed have greater cohesion and hardness than the lower-half when it dried.

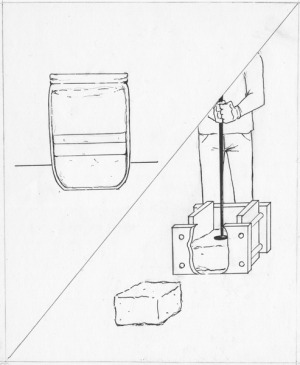

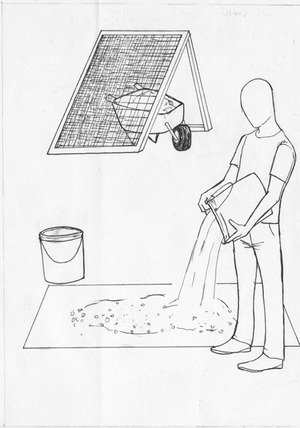

Plate 4 - Sifting and Mixing the Soil

In order to remove large concretions of the soil, I sifted the excavated soil through a 1/2" mesh screen. I understand that when stabilizers such as cement or lime are added, this soil must be pulverized. On a piece of plywood, I combined the above-mentioned proportions of excavated soil that was sifted and sand. These were mixed dry until they were thoroughly combined. Then, the right amount of water was added (many say this is more of an art than a science) and did a wet mix. When I was happy with the water content, I added and mixed the gravel. The mix for each course of the corner formworks consisted of 3 5-gallon buckets of excavated soil, 1.5 5-gallon buckets of sand and 1.5 5-gallon buckets of gravel. So, six buckets in total.

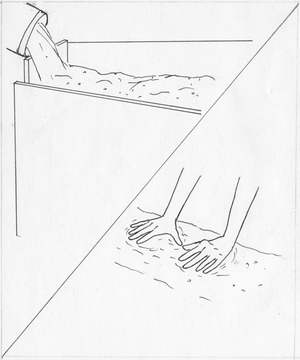

Plate 5 - Adding and Smoothing the Soil

Once the mix was ready, I added it to the formwork. I then smoothed it out, and 6 buckets of mix gave me 5" of mix to be compacted. Five inches is the amount recommended by Karl Ellington and worked well.

Plate 6 - Bevelled Corners, Corner Reinforcement and Keyways

Plate 6 - Bevelled Corners, Corner Reinforcement and Keyways

To increase the strength of the corners, I added bevels in each corner. This allowed for a more complete ramming of the earth in the corners. Per Karl Ellington's recommendation, I added reinforcement in the corners. I used wire fencing, which is commonly used as remesh in concrete work. I added this mesh in every other course in the corners. Also per Karl Ellington's suggestion, I added keyways at all the openings, which will allow for the window and door jambs to be added. In addition to bevelling the keyways, I attached chain to the back of them and embedded it straight back into the rammed earth wall.

Plate 7 - Ramming

To ram the earth, I used three rammers. The first rammer, the Boden-Hauser, was made of birch wood covered with metal plating, and had a 4' iron pipe handle. Its face was about 5" x 6" and was nice to make the initial compression. The second rammer, the Franken-Hauser, named after the gentleman Frank who welded it for me, had a 4" x 3" face and had a 4' pipe handle. This rammer face had a straight-edge to really ram the edges of the formwork. It compressed the soil really well, and probably compressed it to a sufficient amount without any additional ramming required, but I used a third rammer for the final compression. The third rammer, the Black Widower, so named for its color and because it killed a black widow that tried to bite me, is a standard digging rod with a 2.5" circular tamper on the non-digging side. This really compressed the soil just a bit at the end, but it seemed to make it non-porous and really hard. All the rammers were covered with Tyvec to prevent the soil from sticking to it. The two bigger rammers would need to be recovered about every 6-8 courses, and the black widower needed to be recovered every course. I folded the Tyvec over twice to give me four layers of Tyvec. By the end, I could mix and ram a corner course in one hour.

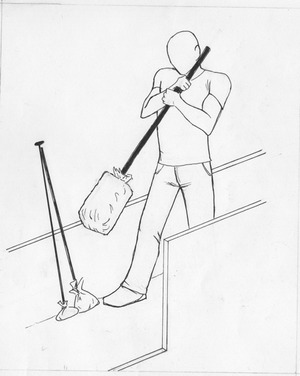

Plate 8 - Removal of the Formwork

Once the formwork was filled to the point I wanted, I removed the formwork and admired the freshly tamped earth. I probably spent too much time on the latter part of this step because its so damn pretty. It's also amazing that I could take the formwork off as soon as I finished tamping without having to wait for it to cure.

Six months may seem like quite a long time to complete a relatively small project (small is a sort of, well, funny term to use with rammed earth, as the walls of the Boden-Haus weigh about 20 tons). In fact, it is. I made many mistakes and time-consuming decisions that added to the time-frame of the Boden-Haus's construction. However, these mistakes and decisions taught me much. Before I started the project, I'd read so many writings on rammed earth. And yet, when I reread those works after working on the Boden-Haus, I saw sentences and diagrams that I completely missed the first, second and third times. This brings me to the obvious question, "What would I do differently?" Well, I probably wouldn't have dug the holes for the soil. That took around 3 weeks, and one can easily source soil and have it dropped off for a reasonable or even free price. Finding construction sites and asking them for the soil is one way to get soil. Also, I probably would have not spent the time getting the stones for the foundation from the sinkhole. While it was nice that about 30 percent of stones from the site where the Boden-Haus was being built, it was incredibly time-consuming, and not worth it in the end. Plus, the stones were much more difficult to build with then the ones we purchased from the quarry. They were all river stones, but you can pick and choose when you go to a quarry. Just those two things would have saved about six weeks. The one thing I would have changed about the actual ramming is the mixing. Mixing is by far the hardest part of the process, and one person with a mixer could cut the time of the ramming in half.

The Boden-Haus is the hardest thing I've ever done, and I'm so happy I did it. I bled, I sweated, and almost cried a few times. I am very grateful to Robert and Rachel for allowing me to be with them for such a long time, to learn so much from them and to have many fun times with them. I'm also grateful to them and Tom and Carla for allowing me to build my first project on their land, a very beautiful place indeed.

My gratitude also goes out to the following people for their work on the Boden-Haus: Kate (worked for a dollar a day, and did it with a smile), Jacob (Rachel's brother, dangerously precise and really nice to work with), Michelle (a mental rotator extraodinaire making her an exceptional stone mason), Mike (man he works hard), Vanessa (two excellent trips from Nashville to help, and she really did. She didn't seem to tire) , Jacob (my brother, helped me tear down the first corner and build up another section, almost matches me in amount he sweats), Corey (after driving from Florida, dug all day in blistering heat without complaint), Uncle Warren (tightens formwork bolts with the best of them), Noah and Justine (already named the best contractors in East Tennessee, great people and really supportive of this "crazy" project), John (he came down with intentions to work really hard, but it was a betwixt and between part of the Boden-Haus. He gets an shout-out for his intent) and Jess (she laid the best stone in the foundation).

Already thinking about my next project.

References (2)

-

Response: Galvanized Iron Pipes SupplierRajat Traders is a renowned Manufacturer & supplier of Galvanized Iron Pipes from Odisha, India.

Response: Galvanized Iron Pipes SupplierRajat Traders is a renowned Manufacturer & supplier of Galvanized Iron Pipes from Odisha, India. -

Response: https://funded-traders.com/

Response: https://funded-traders.com/

Reader Comments